According to the current situation of prevention and control of pneumonia caused by NCP, the first-level response mechanism of major public health emergencies has been started in Guangdong Province. In accordance with the deployment requirements of the prevention and control work of government departments and to further implement the relevant requirements of government departments on the prevention and control of NCP. We will spare no effort and carry out the prevention and effective production safety of the company and the safety and health of the employees in the production environment.

- working group on epidemic prevention and control

- The working group is mainly responsible for the epidemic prevention and control work in the factory during the epidemic prevention period, carrying out epidemic prevention and control measures in an all-round way, organizing and mobilizing relevant resources of the factory to deal with emergencies or abnormal situations that affect the epidemic control work, and timely reporting the work progress to the superior epidemic control leading group.

Members of the working group as follows:

Outbreak prevention team leader: Mark Yang

Employee turnover statistics: Lawrance Lin

Daily diagnostic isolation: Jelly Chen

Dormitory disinfection: Wang

Epidemic publicity and education: Miss Liu

Preparation of protective equipment: Lawrance Lin

- 2 Plan of epidemic prevention and control

- 2.1Personnel Management

The company will inform the employees ,who are still in HuBei province and who with travel history or residence history or close contact history in HuBei province since Jan.10th , to suspend their return to work.After 14 days of self-isolation, or after the outbreak is stable and controllable, I will contact the company to confirm the application for returning to the factory.The personnel department is responsible for following up and reporting statistics to government departments.

Other personnel who in addition to the above situation with normal physical condition can be back to work on the day.

- 2.2 Plant Control:

All personnel must wear face masks at all times when entering or leaving the plant . It has to be sterilized before entering the plant , then wearing protection suit , gloves, shoe covers, goggles, no personnel are allowed to enter the plant who without masks , departments and individuals that fail to comply with the regulations will be prohibited from entering the plant. All personnel will be lined up in front of the Gatehouse for temperature measurement, shoes, hands and luggage to be fully sprayed with javel water before entering the factory. All staff use face recognition card instead of the fingerprint card to reducing skin contact. Someone will be forbidden to enter the factory if his/her temperature abnormal, then will report to the epidemic prevention and control working group emergency handling. The machines are disinfected four times a day, the cleaner disinfects the elevator and the buttons every 2 hours, the toilets on each floor are disinfected every day.

- Control Of External Personnel :

Our factory stringent controls the external personnel and vehicles entering, as far as possible take video and telephone communication for external business. All visitors are required to wear masks when entering our factory. Visitors are required to do body temperature monitoring before entering plant. Thenregister any information about the name, telephone number, recent visit to Hubei Province and others.

- Staff Dormitory Access Control:

All staff who living in the dormitory are required wearing mask in common areas such as staircases in dormitories. Dormitory attendant has regular disinfection, epidemic prevention and ventilation of the dormitories.

- Management Of Staff Canteen:

It will use different posts staff staggered peak diversion approach for all staff. Staffs are requested to wash hands with instant sanitizer before eating.Only allowed to take off the mask at the time of eating. All personnel sit one meter apart not opposite, not talking, and leave immediately after eating.

.

2.6 Management Of Epidemic Prevention Materials:

In accordance with the regulations and requirements of epidemic prevention and control, the epidemic prevention materials provided by our factory include: Masks, gloves, temperature measuring machine, disinfectant, 75% alcohol, hand lotion, disinfectant sprayer, portable sprayer, etc. . The personnel department is in charge of them.

Notes:

1) Chlorine-containing disinfectants are irritating to the skin and mucous membranes, and masks and gloves should be worn when configured and used.

2) 75% alcohol is flammable, alcohol disinfectant should be used away from the fire source. Please covered it after using.

- Management of Epidemic Prevention and Control Operation:

In order to ensure the staff’s prevention and requirements are effectively implemented during the epidemic control period, epidemic prevention and control team will organize personnel to carry out random on-site inspection of the implementation situation. Then the checking results of the temperature samples will be informed of the problem identified by the designated responsible person and responsible department to implement corrective measures.

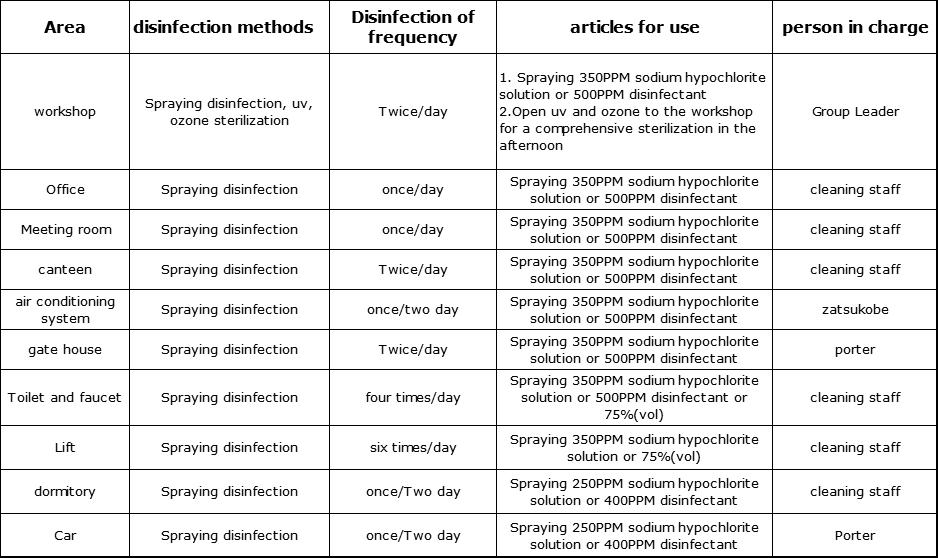

Table Of Epidemic Prevention and disinfection

Work flow of epidemic prevention and control

Conclusion:

During the epidemic prevention, please cooperate with the factory inspection to ensure your safety.

Let us make better performance together in the 2020.

Thanks all colleagues.

SUAPCK INDUSTRY CO.,LTD.

2020.2.10

Leave A Comment